|

Dr. Christopher R. Kelson, PhD, PG

Senior Geologist

Atlantic Testing Laboratories

Cyclic changes in temperature, which cause liquid water to alternatively freeze and thaw within saturated, hardened concrete, can damage the concrete when the water within capillary pores and microcracks in the cement paste freezes and turns to ice. Concrete paste with a high water/cement ratio can be especially susceptible to freeze-thaw damage, since it contains a correspondingly high volume of capillary pores within which liquid water can reside. Repeated and alternating freeze-thaw cycles forces water to migrate to other places within the concrete where it can then freeze and expand again, causing cumulative damage to the concrete over time.

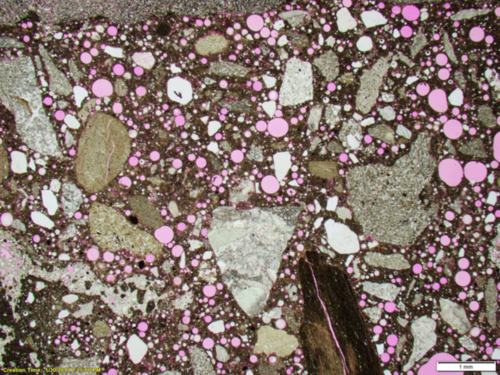

Blending special admixtures with fresh concrete forms numerous, small, spherical, discrete voids within the paste to create an entrained air-void system that is a good defense against freeze-thaw damage. The entrained air voids provide space to accommodate the internal pressure associated with the expansion of water upon freezing within the concrete. Entrained air voids are different from the entrapped voids formed naturally in concrete during placement. Entrained air voids are spherical in shape, smaller in size (≤1mm), homogeneously distributed in the cement paste, and are more abundant than entrapped air voids. The total percentage of air needed for concrete to resist the effects of freeze-thaw ranges from 4.5% (mild exposure) to 9% (severe exposure) and is dependent on the severity of exposure the concrete will have to continuous moisture, changes in temperature, and deicing salts.

|

|

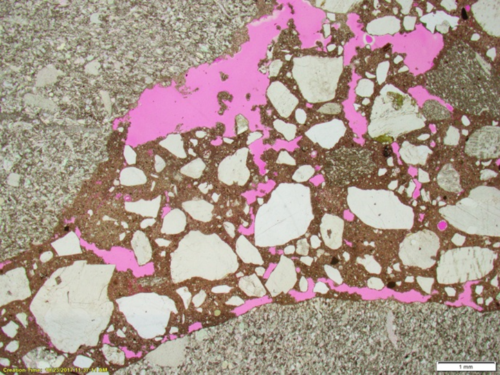

Photomicrographs illustrating the differences in shape, size, distribution, and abundance between entrapped air (pink, LEFT) and entrained air (pink, RIGHT) within hardened concrete paste (brown). Aggregates = white, gray, and/or tan-colored angular shapes. Plane-polarized light; magnification x12.5.

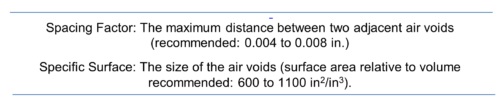

ASTM C457 Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete outlines and describes the optimal air void system parameters recommended for hardened concrete to best resist freeze-thaw damage. In addition to the total percentage of entrained air, other important parameters of the overall air-void system include:

|

For more information, contact Dr. Christopher R. Kelson, PhD, PG at 315-386-4578, CKelson@AtlanticTesting.com.