Click the following link to view the PDF of this paper: Practices for Field and Laboratory Evaluation of Thermal Resistivity

Royce A. Knowlton

Operations Manager

Atlantic Testing Laboratories

In the design of heat generating underground utilities, such as electrical conduits, understanding the ability of the surrounding media to dissipate heat is a key parameter for design. Thermal resistivity, referred to as Rho (ρ) value and expressed in units of C.Cm/W or C.m/W, is the measure of resistance to heat flow through a material such as soil, concrete, or Fluidized Thermal Backfill (FTB) used as backfill or encasement for underground utilities. For electrical installations, the rate at which underground conduits can dissipate heat is a controlling factor in determining the ampacity of the system. Thermal resistivity testing can be completed in the field and laboratory, both use similar methodology and equipment. The following is a discussion of each method and the advantages and limitations.

Background

The two common standards for the determination of Rho value for underground utilities in the field and/or laboratory are ASTM D5334 (Determination of Thermal Conductivity of Soil and Rock by Thermal Needle Probe Procedure), and IEEE 442 (IEEE Guide for Thermal Resistivity Measurements of Soils and Backfill Materials). Both methods make use of a thermal needle probe, consisting of a resistance wire and temperature sensor. The needle is inserted into the specimen and a known current is applied to heat the specimen, while temperature readings are recorded over time and used to calculate the Rho value of the specimen. Rho value is dependent on material properties, such as density, porosity, moisture content, and elemental composition.

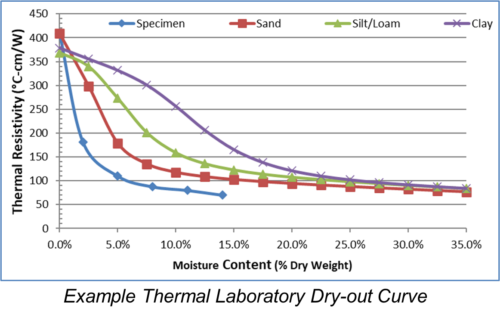

For utility applications, the thermal Rho value for a material is most influenced by the moisture content. The relationship between the moisture content and Rho values is represented graphically and is commonly referred to as the Thermal Dry-out Curve. The tangential point between the flat and upward sloping portions of the graph is known as the critical moisture content. The critical moisture content is the point at which a marginal decrease in moisture content will result in a large increase in the measured resistivity.

Field Testing

Thermal testing of the existing soil/rock materials along the proposed utility route is completed during the design phase to evaluate existing materials that will be in the zone of influence of the proposed utility. In most cases, proposed utility depths allow for shallow test pit excavations to access the existing materials for testing.

Advantages:

- In-situ thermal testing can be performed in conjunction with test pit excavations for geotechnical evaluation of soil and groundwater conditions, saving time and costs.

- Field readings are obtained directly on relatively undisturbed material, and therefore more accurately reflect the density and moisture condition of the in-place soils.

- Field thermal readings can be quickly obtained on multiple materials encountered within the proposed route or at varying depths in the existing soil profile.

- Materials can be sampled for further laboratory testing, such as index properties and development of a thermal dry-out curve.

Limitations:

- Field testing alone does not provide information on changes in resistivity at varying moisture levels i.e., thermal dry-out curve.

- Testing depths are limited to safe/practical depths of excavation.

- Not suitable for evaluation of materials for reuse as trench/utility backfill, as Rho value at specified compaction and moisture content are unknown without laboratory confirmation.

Laboratory Testing

During the design phase, and construction, thermal laboratory testing can be used to evaluate existing and proposed materials that will be in contact with the utility.

Advantages:

- Allows for development of a thermal dry-out curve and testing is performed in a controlled environment.

- Materials proposed for reuse or imported materials can be tested at a specified density or % of proctor value (ASTM D1557 or D698), to aid in development of project specifications.

- Can be used to evaluate compliance of imported materials prior to and during construction.

Limitations:

- Field samples must be obtained in an undisturbed condition and transported to the laboratory without damage and/or moisture loss.

- Materials must be sampled without disturbance or be remolded to reflect the in-situ conditions. Remolded density and porosity may not accurately reflect the in-situ conditions.

- Submitted samples may not capture variations in materials throughout the proposed route.

There are practical limitations to testing in both the field and laboratory. Field readings alone do not typically provide enough information on thermal properties of materials for design, as these are a snapshot at a particular condition and moisture content. Laboratory tested samples may be disturbed during sampling and/or need to be reconstituted to represent field conditions. Depending on site conditions, obtaining samples that reflect varying site conditions may be difficult. A properly developed subsurface investigation and testing plan for a utility project addresses sampling and testing for thermal resistivity, including testing limitations in the field and laboratory. The size and scope of the project, existing conditions, soil types, and proposed depths of the utility will be factors for determining the appropriate scope of field and laboratory testing. In most cases, a combination of field and laboratory testing will provide the most comprehensive information for design and construction.

If you have a project that may need thermal resistivity testing or soil and aggregate laboratory testing, ATL, a WBE certified company, offers a wide variety of consulting services. For more information, contact Royce Knowlton at 585-427-9020, info@atlantictesting.com, or visit AtlanticTesting.com.

|

ASSOCIATED SERVICES |

|